Brazing Filler Metals

Aluminum Brazing Filler Metals (SKA SERIES: Pre-fluxed Brazing Filler Metals)

The “SKA Series” products are compacted aluminum-powder preforms manufactured with uniform, optimized particle-sized powders, which minimize oxidation and maximize brazeability. They are pre-fluxed brazing filler metals, where filler metals and fluxes are uniformly mixed throughout. Because the pre- and post-brazing cleaning steps can be omitted, it reduces cleaning costs and prevents the generation of waste acids such as sulfuric and nitric acid. In addition, it eliminates the chlorine (Cl)-related environmental pollution associated with conventional processes and helps maintain a clean working environment.

Aluminum Brazing Filler Metals (SU SERIES: Flux-cored Type Brazing Filler Metals)

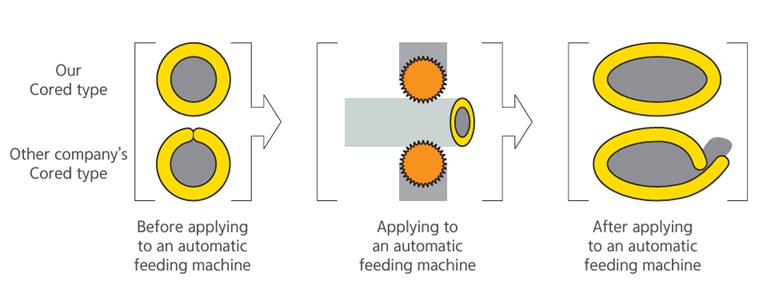

The “SU Series” products complement the weakness of “SKA Series” products in terms of ductility, making it suitable for wire auto-feeding brazing. They enable joining of dissimilar metals (Al–Cu, Al–Brass, Al–STS) and allow low-temperature bonding (450 °C). In addition, a completely new manufacturing process—different from the conventional wire seam cored types used by other companies—has been applied, resulting in improved quality and performance. The “SU Series” products are aluminum brazing filler metals with flux contained in their cores.

Silver Brazing Filler Metals (BAg)

Silver Brazing Filler Metals are Ag-based brazing alloys used for joining stainless steel and other steel components, and are also widely applied to non-ferrous materials such as tungsten alloys, titanium alloys, cemented carbides, diamond, precious metals, and brass. They are broadly available in cadmium-bearing and cadmium-free grades; the appropriate alloy should be selected according to process conditions, required physical properties, and brazing temperature.

Copper Phosphorus Brazing Filler Metals (BCuP)

These copper alloys—copper-phosphorus (Cu-P) and copper-silver-phosphorus (Cu-Ag-P)—are widely used as brazing filler metals for joining copper and copper alloys. Phosphor-copper filler metals provide excellent electrical conductivity and mechanical properties at the joint and offer superior resistance to sulfuric acid and similar media; however, they are not suitable for ferrous materials such as steel.